EVERYTHING is done by hand in our garage in Rialto, CA.

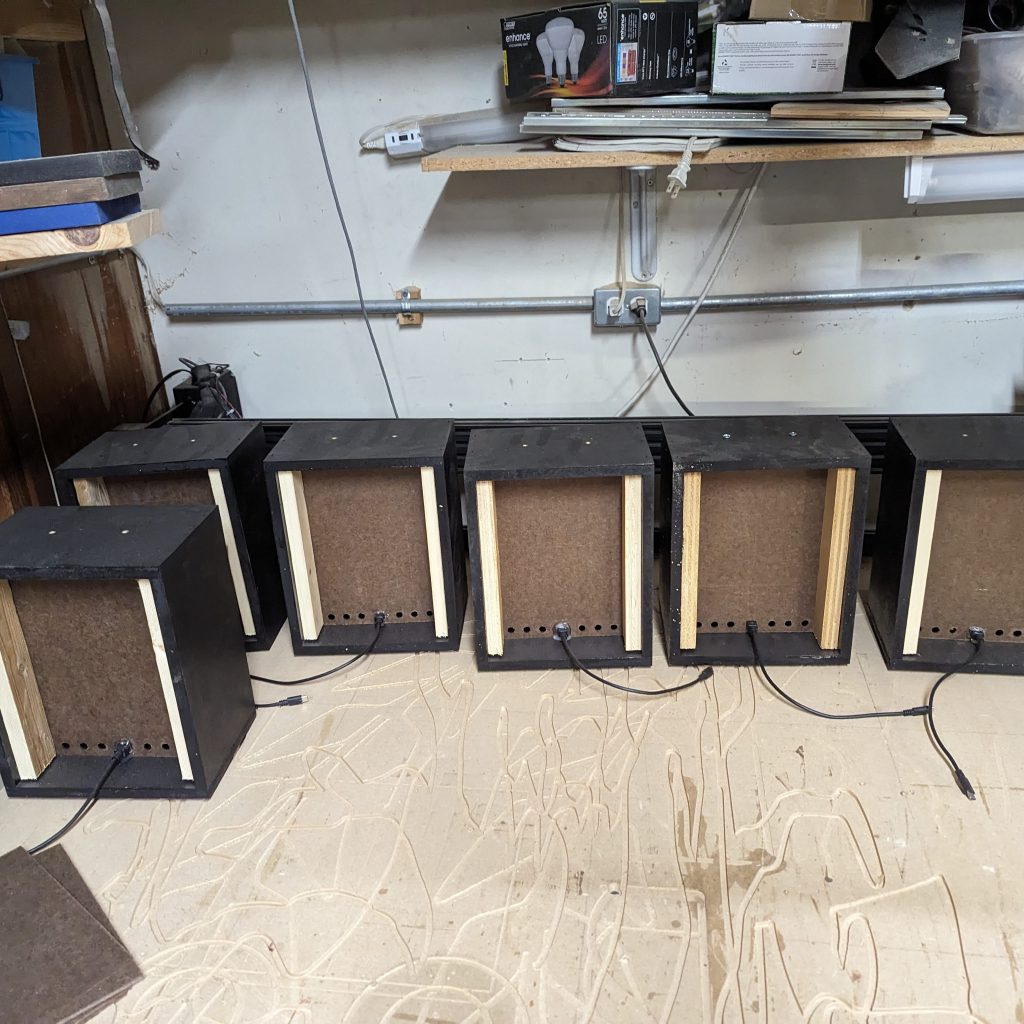

Step 1: We cut the box pieces from 8’x4′ MDF sheets and assemble the same with staples and glue. Once dry, they are sanded and then painted and handles and feet installed.

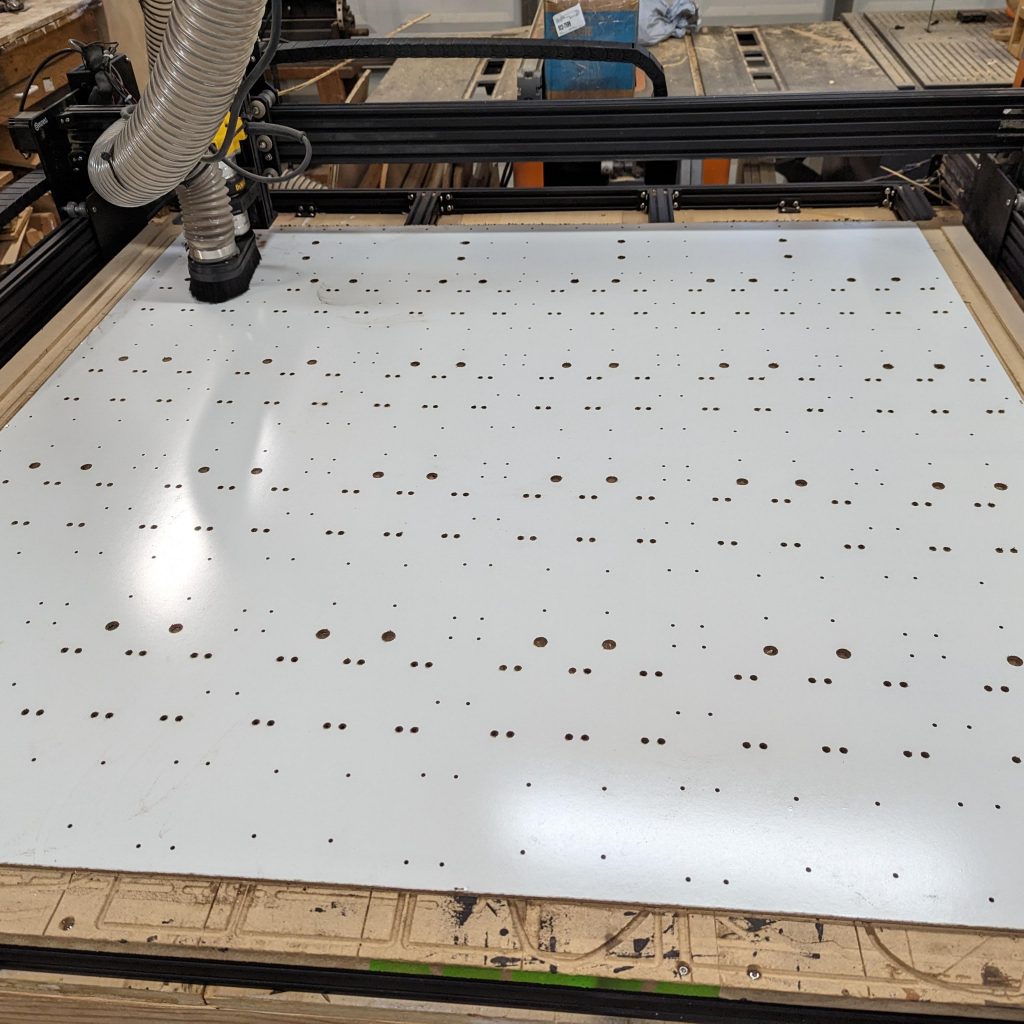

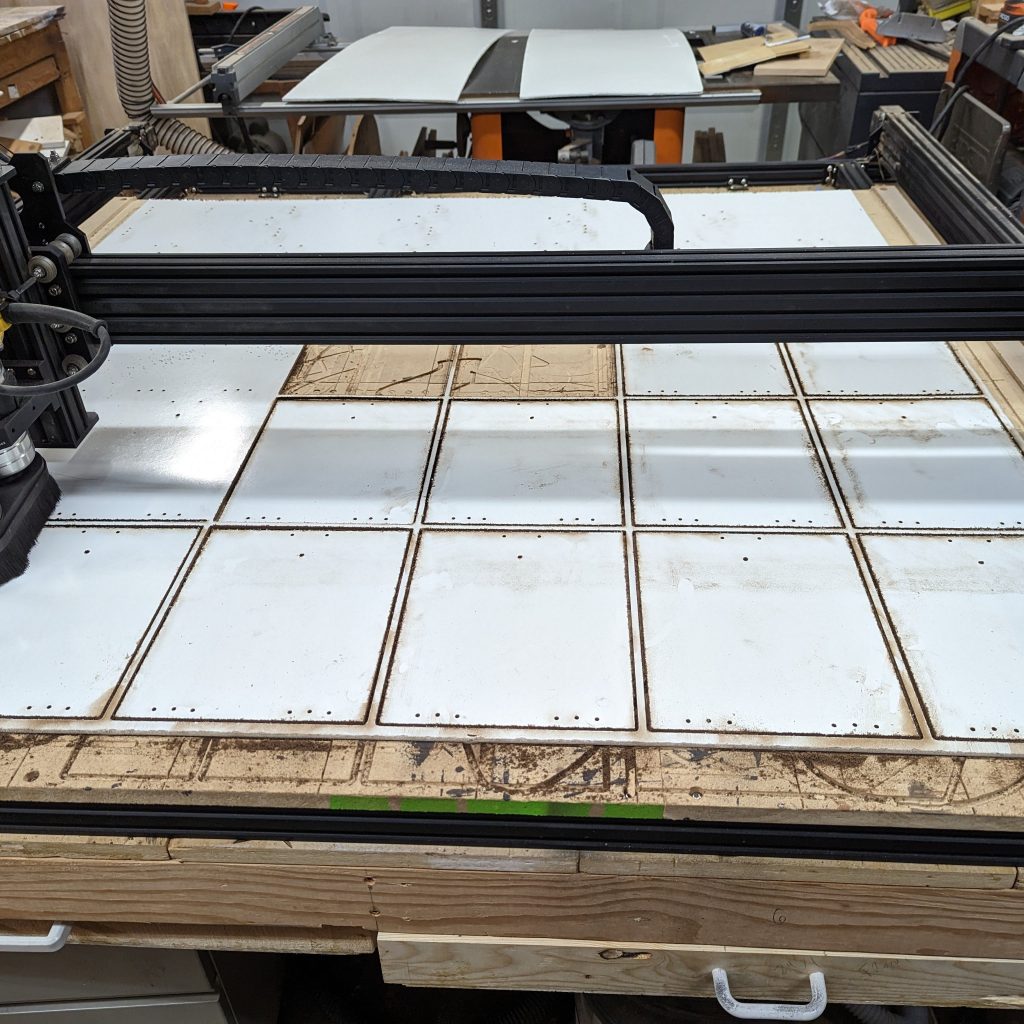

Step 2: We use our CNC to cut the 3 plates (front, middle and rear)…

Step 3: If a custom engraving is requested, we use our new laser to imprint the design (image shows it being done with a CNC which we did prior to this purchase)

Step 4: The plates are then mounted into the boxes…

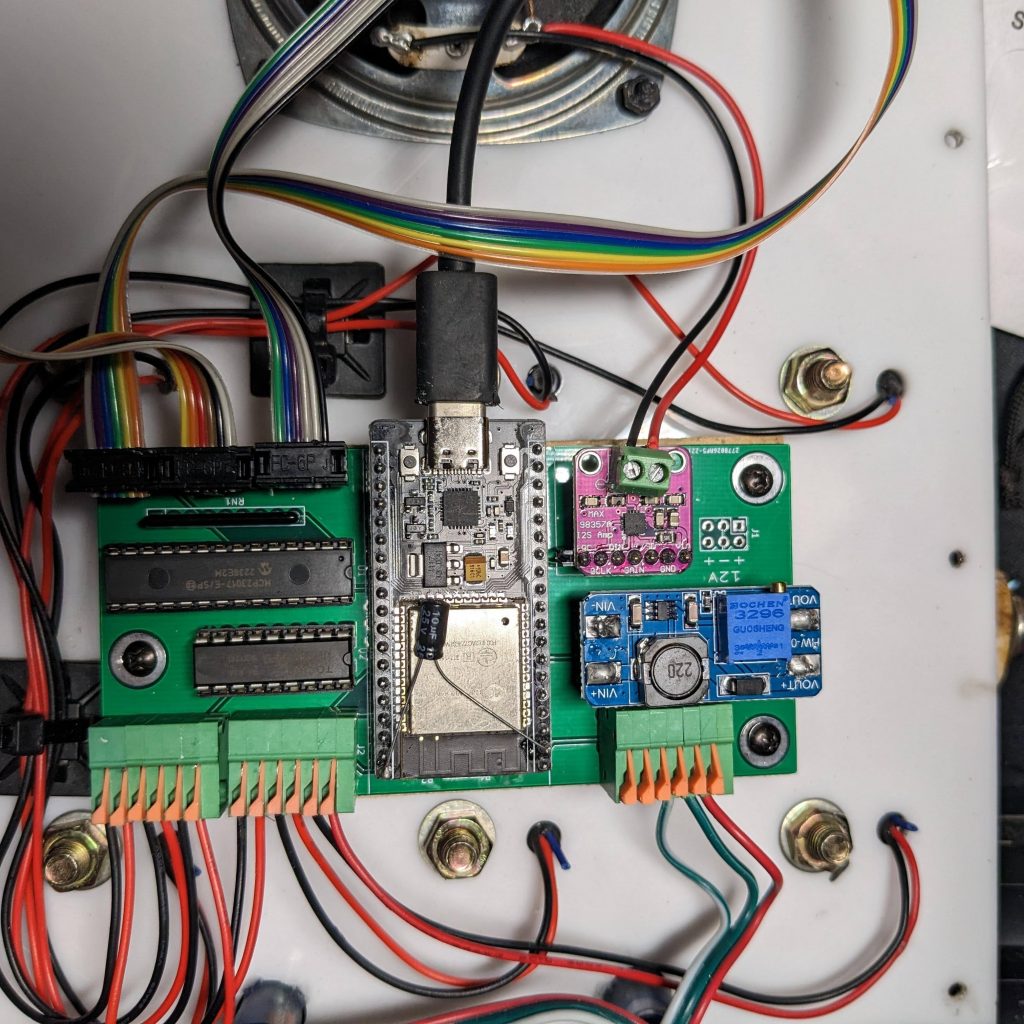

Step 5: The electronics are soldered to custom PCBs and programmed with the latest firmware

Step 6: The handles are then drilled, wire fed in, RCA jacks attached, buttons soldered everything heat-shrunk and glued in place…

Step 7: Final QA check are done to ensure that everything is working perfectly and then the buzzer is packaged and shipping to you!